CALL NOW:

424-999-7170

CALL NOW:

424-999-7170

If you have a concrete patio, you may be wondering what you can do to fix peeling epoxy. You have a few options. You can try heating up the area with a heat gun. The heat will soften the epoxy and will allow you to remove it with a plastic scraper. If you aren't too worried about damaging the surface, there are other easy ways to fix peeling epoxy, such as using a heat gun to soften the epoxy.

In this article, we’ll explore some of the causes of peeling epoxy and simple tricks to fix this issue.

There are several common causes of peeling epoxy, and avoiding them is crucial for the longevity of your finished project. One of the most common causes of peeling epoxy is improper preparation. If you mix oil or grease into your epoxy, the result is a discolored surface. This process can result in inconsistent coloration or peeling of the coating. In addition, improper prep can lead to inconsistent coloration. Therefore, many people will need more than one epoxy kit to complete the job successfully.

Inaccurate floor prep is another common cause of peeling epoxy. When the surface is not properly prepared, the resin will be unable to harden correctly and may peel off. This can happen with an epoxy floor coating, especially if a DIY or inexperienced person installed it. A properly prepared floor is the key to preventing peeling epoxy. Following the manufacturer's instructions when installing an epoxy floor is critical.

Incorrectly mixed epoxy can also result in blisters. These bubbles can occur due to improper mixing of parts A and B. The problem is caused by air bubbles remaining in the viscous epoxy. If you suspect an improper mix, you can either use a new epoxy mix or re-mix the old one. If the bubbles are severe, you can simply vacuum them up to remove them. If the bubbles are minor, they will eventually disappear.

Excessive moisture is another common cause of peeling epoxy. The right balance of hardener and resin can prevent cracks and peeling. If you choose the wrong hardener, you may end up with a yellowish or uneven surface. Other possible causes of peeling epoxy include the presence of carbon monoxide or other chemicals. If you've recently installed an epoxy floor.

Regardless of the cause of your peeling epoxy flooring, there are simple solutions to these issues. If the problem is localized, patching up is an easy way to solve it. However, remember that patch jobs will always be visible, and the seams will eventually pick up dirt. Taking the time to patch up your floor is a cost-effective solution to peeling epoxy flooring. You'll notice an improvement in your floor in just a few months.

If you have a peeling epoxy coating, you are probably wondering what you should do. The best way to fix this problem is to apply more than one coat of epoxy. In addition to this, the resin on the surface should be applied at a thickness of about 1/8" or less. Be sure to use fresh resin and hardener. Also, follow the mixing instructions carefully, as this will help you avoid setting back your project.

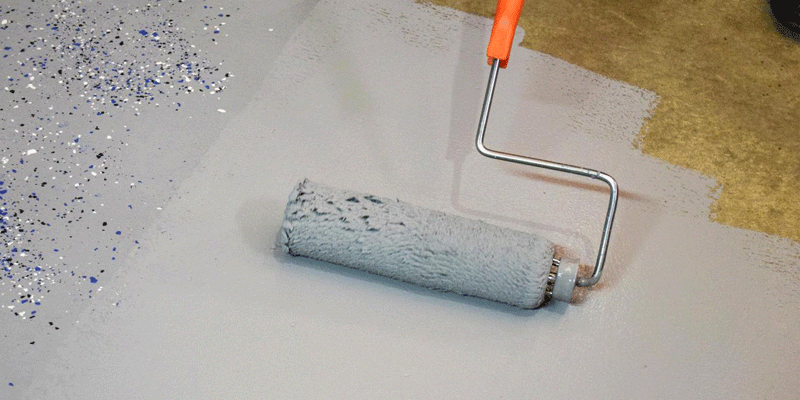

The first step is to make sure that the floor is completely dry. If the floor is wet, the epoxy will not adhere properly to it. Also, if the floor is dirty or rough, it will not harden properly, and you will end up with a peeling epoxy floor. To prevent this, it is best to make sure that the floor is clean, dry, and smooth before applying the epoxy. This will help you avoid the problem of peeling epoxy flooring.

If the surface is scratched and has small fissures, you can repair it by troweling the compound into the affected area. After that, wait 60 days for the mortar to dry and then reapply the epoxy over it. Alternatively, you can also use epoxy patching kits to replace the mortar. But if the damage is extensive, you should consider resurfacing your entire floor. However, if you want to avoid the hassle of hiring a professional, make sure you follow the instructions carefully.

The second step is to inspect your floor for discoloration visually. Scrape the top layer of the floor with a knife to see whether there is a difference in color. If you notice that there is a huge difference, then your floor is likely discolored. If you can spot the discoloration, you can treat it quickly by applying a stain that covers the entire floor. If you cannot find any, you can apply another coat of stain to cover the discoloration.

You can always retouch the floor with new epoxy if you can't get a contractor to remedy the problem. You can use solvent-based epoxy, which is more effective than water-based ones. Just make sure to clean the area thoroughly before you begin. You must be sure to wear protective clothing and take all necessary safety precautions when working on a floor that has peeling epoxy. If you do not get a professional to fix your flooring, you may want to look into replacing it with another type of flooring.

The worst cause of peeling epoxy is a badly prepared concrete surface. The surface profile is a key factor in the mechanical bond of epoxy to concrete. Most epoxy needs a CSP 1 or CSP 2 profile. Obtaining the correct surface profile is easy when you pay attention to details. If you do the proper preparation, you can be confident that your flooring will last for years. When it comes to garage floors, the best way to avoid a peeling epoxy floor is to hire a professional to do the job.

Peeling epoxy can be a sign of improper application. Applying a second coat of epoxy over the old one can result in a peeling surface. If this happens, make sure to grind off the old paint first with a grinder and then apply the new epoxy coat on top. The following tips can help you prevent this from happening. When applying a new coat of epoxy, make sure to wear protective gloves and a respirator.

Check for any discoloration on your concrete floor. If the paint is discolored, this means that there was moisture in the concrete before it was applied. If this is the case, you should contact the applicable company and ask for a fresh coating. If the coating appears uneven, it can mean a number of problems. For example, the epoxy might have dried too quickly or been applied too thinly.

If the concrete is covered in a sealant, epoxy will not bond properly to it. If the floor is coated with a sealant, you can grind it away or use an acid etching solution. This will help improve bonding, preventing the epoxy from peeling. While grinding and acid etching can help remove the sealant, they are not a reliable solution to preventing peeling epoxy.

The best way to prevent peeling epoxy from your garage floor is to avoid moisture. When you wash the floor with water, make sure it dries completely before applying the second layer. Moisture accumulation can ruin an epoxy coating, so make sure you remove all water within 24 hours. Alternatively, use floor mats to remove mud and water from your shoes and ensure you dry your feet before entering the garage. In this way, you'll prevent peeling epoxy from happening!